Build With The Best

At Nagarjuna Steels, we understand that the success of every dream depends on a strong foundation. And that strong foundation is provided by our incredible TMT bars. Welcome to Nagarjuna Steels. This is where you discover why our TMT bars are the best for your dreams.

Projects

01

Individual houses

0

+

02

High-rise residential projects

0

03

Commercial Buildings

0

04

Residential projects

0

+

05

Bridges

0

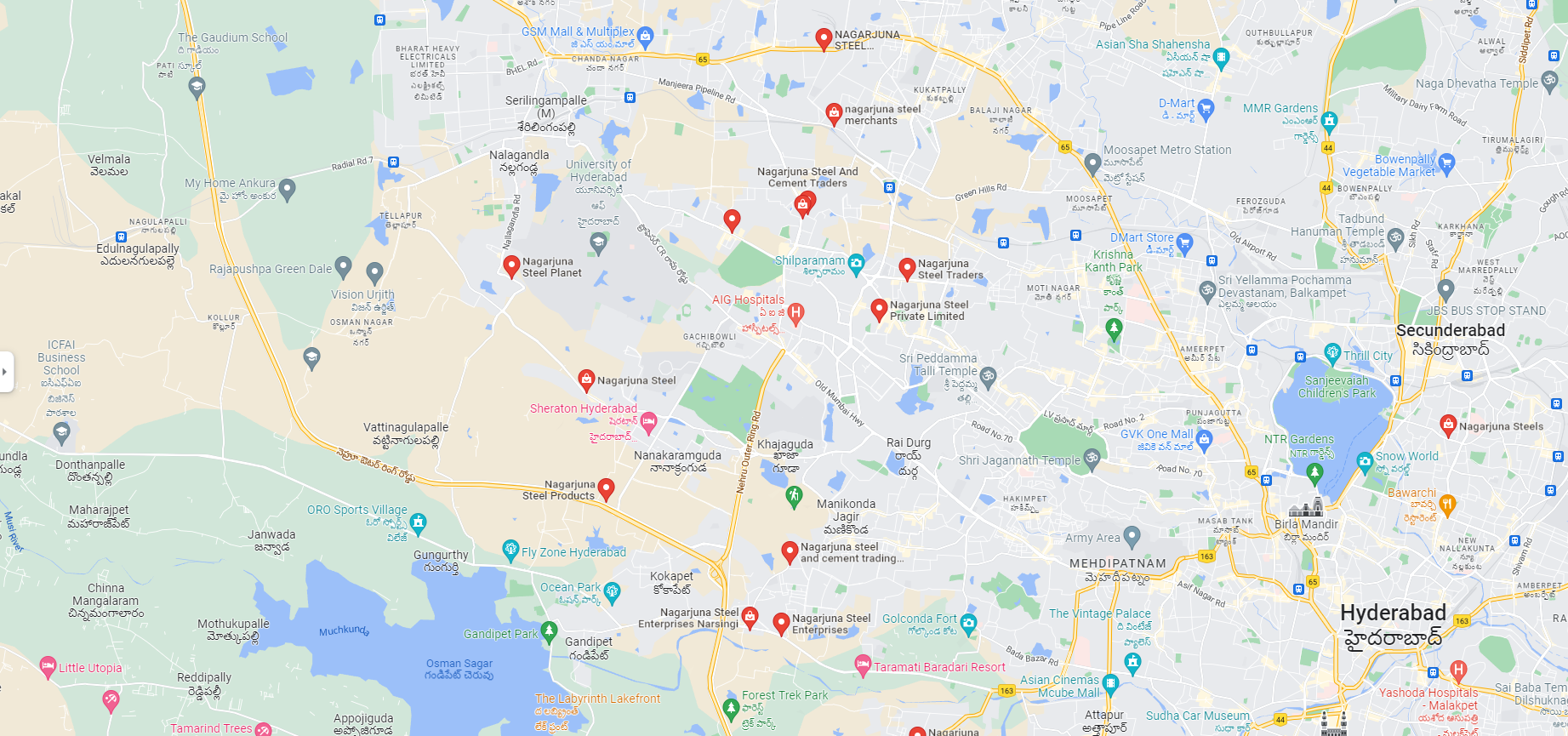

Company Journey

Over the last thirty years, Nagarjuna Steel Pvt.Ltd. (NSPL) has supplied top quality TMT Fe 550 Rebars to the major construction firms in Southern India. Our products are readily available throughout Southern India thanks to our wide network of dealers.

Our Managing Director, Shrl P. Mahender Reddy, has guided the enterprise and its growth from the start, with a strong emphasis on customer satisfaction, efficiency, best practice, and overall integrity. He is the architect of our growth, and the visionary behind our automated production process.

Manufacturing Process

Due to this extensive process, each of our steel bars have greater strength, ductility, bendability and weldability.

The raw material for our steel bars is processed in our in-house induction furnaces. Once the raw material has been melted inside the furnace, the molten metal is separated from the slag.

At this point, we purge the molten product inside a ladle furnace to achieve the desired chemical composition. During this process, we add micro-alloying materials to fix the inherent chemistry of the molten metal. At this stage, excessive non-metallic inclusions are removed from the mix. It is crucial to maintain the chemical composition in order to achieve weldability, ductility, strength and elongation during the rolling process. We keep an eye on the chemical composition with the help of our high-end spectrometer.

Molten metal from the ladle refining furnace is poured into a nearby tundish, which then pours the liquid into a mould located underneath. This process is used to cast a predetermined length of metal, transforming the molten metal mix into a solidified form. New molten metal is continuously supplied to the mould at a precise rate to keep up with the solidifying process.

Our advanced continuous casting machine helps in achieving improved yield, cost efficiency, productivity, and quality.

Once the solidifying billets exit the continuous casting machine, they enter a secondary cooling chamber. Here, the semi-finished billets are sprayed with water to achieve complete solidification. This process is important for maintaining the shape of the solidified billets, improving their quality in the long run.

Next, the solidified metal strands are reheated again in our reheating furnace. This is done to recrystallize the metal, improving quality and reducing material losses. The recrystallization process is very important because the metal strands can then be processed in the rolling mill without destroying the bonding.

The recrystallized metal billets are transported to a cutting-edge rolling mill using conveyors. Here, they are processed using the internationally accepted roll pass design, which makes for higher strength and elongation. This fully automatic process ensures a greater degree of uniformity throughout the length of each bar.

Our state-of-the-art rolling mill technology comprises a roughing mill of two 18” stands, four intermediate mills, four pre-finishing mills, and a finishing mill of six 12” stands. All the stands have individual DC motors to maintain total automation.

After the steel rebars leave the finishing mill with the desired size, they enter a water cooling chamber where they’re subjected to a quenching process. We have an Evcon Turbo machine which employs a unique method for quenching and self-tempering the ribbed steel bars. This treatment is completed in 3 successive stages:

- As soon as the steel rebars leave the final mill stand, they are rapidly cooled to ensure surface hardening.

- Once the quenching operation is completed, the surface layer of each bar undergoes a tempering process with the help of the residual heat left in its core.

- The third stage takes place when the steel bars lie on a cooling bed, where they are subjected to rapid air cooling.

Technical Information

For more information about this product range, please see the technical data sheet.

The Process

Developed To Manufacture Perfection

The high-quality Fe 550 TMT bars manufactured at NSPL are crafted through a tried, tested and perfected methodology to ensure absolute consistency in quality and reliability. Our team is constantly innovating to ensure that each bar is made as efficiently and quickly as possible.

Our Clients

Clients Testimonials

Being a proud dealer for Nagarjuna TMT bars, my clients always prefer Nagarjuna TMT steel bars.

Navya

Nagarjuna TMT bars are high-quality bars & perfect for all types of constructions

Naresh

We as a Infra company have tried many vendors for supply of steel bars. Our search finally ended with Nagarjuna TMT.

Raji